The control and quality of air through the clean room.

Iso 8 clean room air change requirements.

Considerations for iso class 8 cleanrooms high efficiency particulate air hepa filtration is 99 99 efficient at 0 3 micron and should be considered when looking to achieve iso class 8.

A flow hood within the primary control area does in fact influence the overall air change rate of the.

Contact clean air products for cleanroom requirements classifications today contact us for more information on cleanroom standards iso class code descriptions and clean room air changes or request a quote for an in depth price analysis today.

Iso class 8 5 60 air changes per hour with a ceiling coverage of 5 15.

The internal surfaces of the clean room and the equipment within them.

In a normal home an air conditioner changes room air 0 5 to 2 times per hour.

The number of staff.

In room ffu cfm cleanroom air change rates and tables for usp standards.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

Of ffus air changes hour 60 x cubic ft.

Monobloc panel hardwall and softwall cleanroom envelopes are all effective at achieving the environment required for iso class 8.

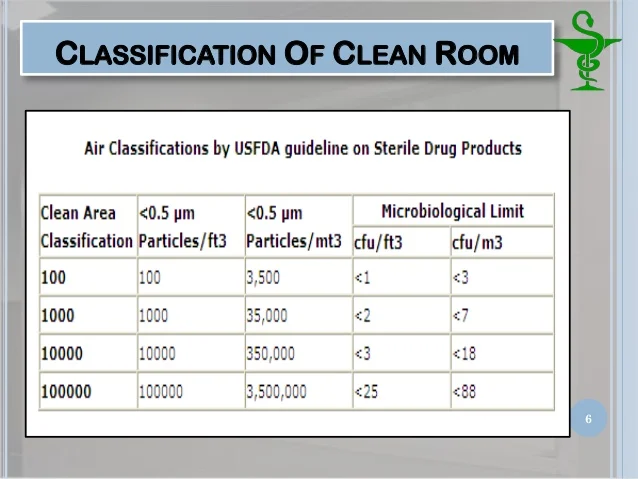

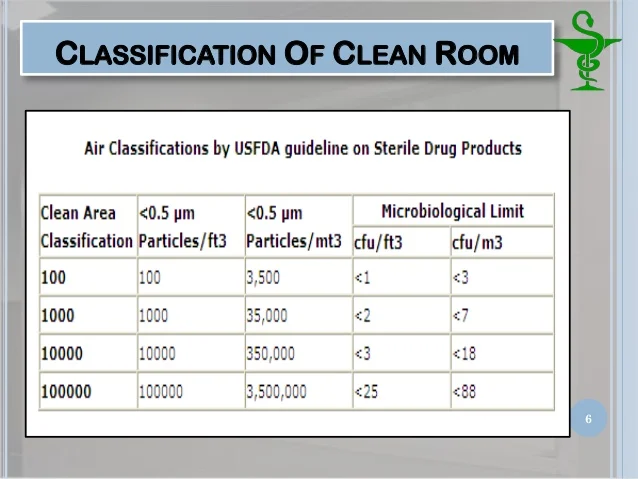

Acr is a prime variable in determining iso and federal cleanliness standards.

In theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image.

In a cleanroom depending on classification and usage air change occurs anywhere from 10 to more than 600 times an hour.

Let s look at them in more detail.